Understanding the Importance of Arc Flash Assessments for Facility Safety

Ensuring workers' safety and equipment's integrity is paramount in the modern industrial landscape. Electrical arc flashes stand out as hazardous events among the various hazards that can pose significant risks in industrial settings. An arc flash, characterized by an explosive release of energy, can lead to severe injuries, fatalities, and extensive damage to equipment. To mitigate these risks effectively, facilities must prioritize conducting arc flash assessments.

Understanding Arc Flash Hazards

Arc flashes occur when an electrical current travels through the air between conductors or from a conductor to the ground. These events release intense heat, light, and pressure waves, often resulting in devastating consequences. Factors such as equipment failure, improper maintenance, and human error can trigger arc flash incidents, making them a potential threat in any facility with electrical systems.

Identifying Risks

One of the primary reasons for conducting an arc flash assessment is to identify potential hazards within your facility's electrical infrastructure. Through a systematic evaluation, experts analyze the electrical systems, equipment configurations, and operating conditions to pinpoint areas where arc flash incidents may occur. By understanding these risks, facilities can proactively mitigate them and enhance safety.

Assessing Energy Levels

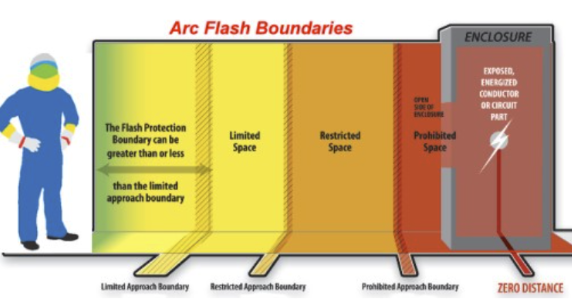

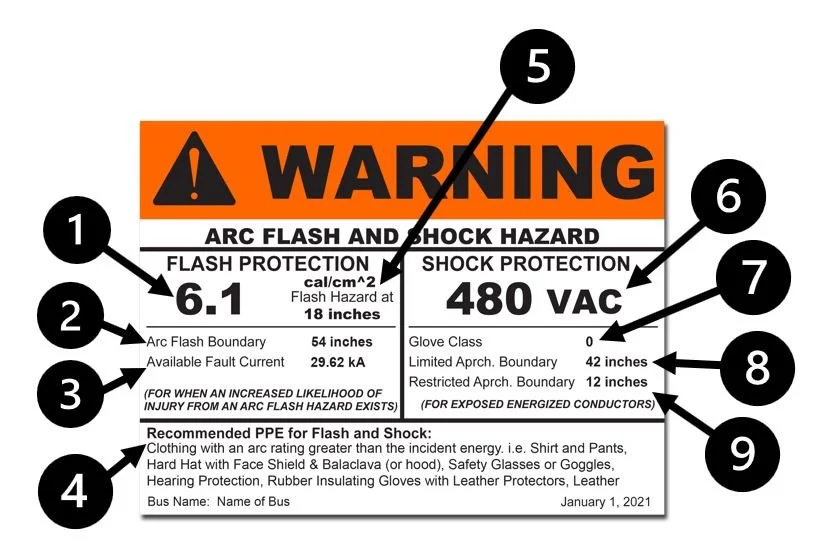

Arc flash assessments calculate the energy levels released during potential arc flash events. This critical step helps determine the severity of possible incidents. By quantifying the energy levels, facilities gain insights into the potential hazards posed to personnel and equipment. This information forms the basis for developing appropriate safety protocols and implementing necessary precautions to minimize risks effectively.

Protecting Personnel

It is of utmost importance that personnel working near electrical equipment are safe. Arc flash assessments play a vital role in assessing the risks faced by workers and establishing measures to protect them. Based on the assessment findings, facilities can implement safety procedures, provide specialized training, and prescribe personal protective equipment (PPE) to mitigate the risks associated with arc flash events. These measures enhance worker safety and contribute to regulatory compliance and organizational resilience.

Ensuring Compliance

Regulatory standards and guidelines, such as NFPA 70E and IEEE 1584, mandate implementing measures to mitigate arc flash hazards in the workplace. Conducting arc flash assessments enables facilities to ensure compliance with these regulations and standards. By adhering to established safety protocols and best practices, facilities prioritize employee safety and minimize the risk of arc flash incidents.

Protecting Equipment and Infrastructure

Arc flash incidents can cause significant damage to equipment and infrastructure, in addition to the risks posed to personnel. The intense heat and energy released during these events can result in equipment failures, downtime, and costly repairs. By conducting arc flash assessments, facilities can identify vulnerabilities in their electrical systems and implement preventive maintenance measures to safeguard equipment and infrastructure against potential damage.

Conclusion

In conclusion, arc flash assessments are indispensable tools for ensuring the safety and resilience of industrial facilities. Facilities can effectively mitigate the risks associated with arc flash incidents by identifying potential hazards, assessing energy levels, and implementing appropriate safety measures. Prioritizing arc flash assessments protects personnel and equipment and fosters a culture of safety and compliance within the organization. Ultimately, investing in arc flash assessments is a proactive step toward creating a safer work environment and minimizing the potential impact of electrical hazards.

written by: Michael Dresser

National Sales for OEL Worldwide Industries

About OEL Worldwide Industries: OEL Worldwide Industries is a leading provider of industrial safety apparel, renowned for its dedication to innovation, quality, and customer satisfaction. With a diverse range of products and a global presence, OEL continues to set new standards in workplace safety.

oelsales.com | 800.818.2244