Establishing an Arc Flash Safety Culture: Building a Foundation for Workplace Safety

In industrial settings where electrical equipment is omnipresent, the risk of arc flash incidents poses a significant threat to worker safety. Establishing an arc flash safety culture within a company is not merely about compliance with regulations; it's about fostering a mindset where safety is prioritized at every level of the organization. By building a solid foundation of awareness, education, and proactive measures, companies can mitigate risks and create a safer working environment for all employees.

Understanding Arc Flash Hazards

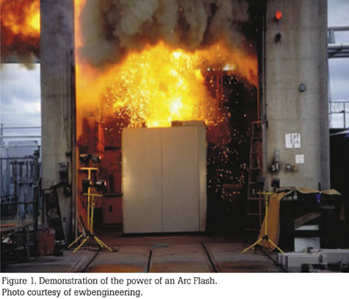

Arc flash incidents occur when electrical current travels through the air between conductors, resulting in a sudden release of intense heat, light, and pressure. These events can cause severe injuries, including burns, blindness, and even fatalities, as well as extensive damage to equipment and facilities. Given the catastrophic potential of arc flash incidents, companies must recognize and address the associated hazards effectively.

One study by CapSchell Inc. estimated that there are between 5,000 to 10,000 arc flash incidents occurring annually in the United States, resulting in approximately 1,000 injuries and several fatalities. However, it's essential to note that this estimate is based on data available at the time of the study and may not represent the current situation.

Leadership Commitment

Establishing an arc flash safety culture begins with unwavering commitment from organizational leaders. Management must prioritize safety as a core value and actively demonstrate their dedication to protecting employees from harm. By allocating resources, setting clear safety objectives, and leading by example, leaders instill confidence and accountability throughout the company, laying the groundwork for a culture of safety excellence.

Comprehensive Training and Education

Education is the cornerstone of arc flash safety. Employees at all levels should receive comprehensive training on arc flash hazards, safe work practices, and emergency procedures. Training programs should be tailored to each employee's specific roles and responsibilities, ensuring everyone understands their role in preventing arc flash incidents and responding effectively in an emergency. Regular refresher courses and skill assessments help reinforce learning and keep safety protocols in mind.

[click] OEL Electrical Safety Training Services

Risk Assessment and Hazard Mitigation

Conducting thorough risk assessments is essential for identifying potential arc flash hazards within the workplace. Companies should evaluate electrical systems, equipment, and work processes to determine the likelihood and severity of arc flash incidents. Based on the findings of these assessments, appropriate hazard mitigation measures should be implemented, such as equipment upgrades, engineering controls, and administrative safeguards. By proactively addressing risks, companies can minimize the likelihood of arc flash incidents and protect workers from harm.

Clear Communication and Accountability

Effective communication is critical for maintaining an arc flash safety culture. Companies should establish clear channels for sharing safety information, reporting hazards, and addressing concerns. Arc flash hazard labels should be prominently displayed on electrical equipment, providing employees with vital information about potential risks and required safety precautions. Furthermore, holding employees accountable for adhering to safety protocols fosters a culture of responsibility and ensures that everyone plays their part in preventing arc flash incidents.

Continuous Improvement

Arc flash safety is an ongoing journey of improvement. Companies should regularly review and update their safety policies, procedures, and training materials to reflect the latest industry standards and best practices. Additionally, conducting post-incident analyses and near-miss reporting helps identify areas for improvement and implement corrective actions to prevent future incidents. By embracing a culture of continuous improvement, companies can adapt to evolving challenges and maintain a solid commitment to arc flash safety.

In Summary

Establishing an arc flash safety culture is not a one-time initiative; it's a continuous commitment to prioritizing safety in the workplace. By fostering leadership commitment, providing comprehensive training, conducting risk assessments, promoting clear communication, and embracing continuous improvement, companies can build a strong foundation for arc flash safety and create a culture where every employee feels empowered to work safely and contribute to the company's success. Ultimately, investing in arc flash safety is an investment in the well-being of employees and the long-term sustainability of the business.

About OEL Worldwide Industries: OEL Worldwide Industries is a leading provider of industrial safety apparel, renowned for its dedication to innovation, quality, and customer satisfaction. With a diverse range of products and a global presence, OEL continues to set new standards in workplace safety.

oelsales.com | 800.818.2244