Understanding ASTM D120 Rubber Gloves

In industries where electrical hazards pose a significant risk, personal protective equipment (PPE) plays a critical role in safeguarding workers' well-being. Among the essential protective gear, ASTM D120 rubber gloves are widely used to protect individuals from electrical shock and arc flash incidents. These gloves adhere to the rigorous standards set by ASTM International, ensuring their effectiveness and reliability in electrical work environments. This article will explore the significance of ASTM D120 rubber gloves and their role in maintaining electrical safety.

ASTM D120 Standard for Rubber Insulating Gloves: ASTM D120 is the internationally recognized standard developed by ASTM International for rubber-insulating gloves used in electrical work. The standard establishes requirements for manufacturing, testing, and labeling these gloves to ensure their ability to provide electrical insulation and protection.

Key Requirements of ASTM D120: The ASTM D120 standard outlines several key requirements that rubber-insulating gloves must meet to ensure their suitability for electrical work:

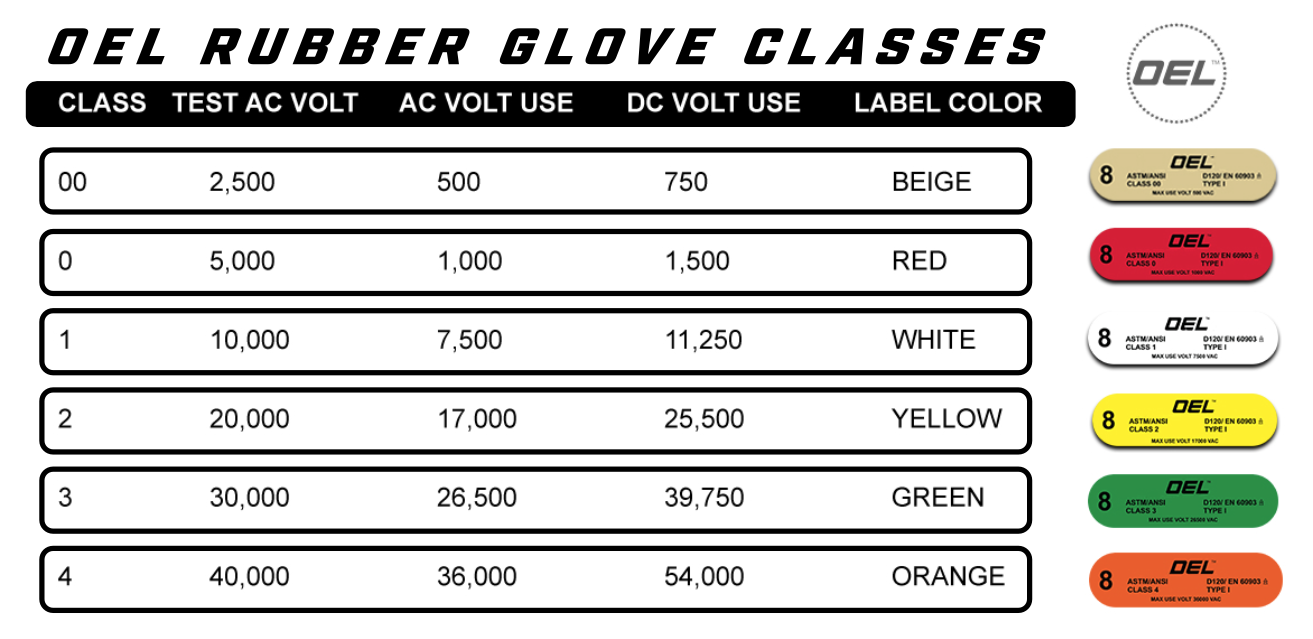

Voltage Ratings: ASTM D120 classifies gloves into different voltage ratings based on their maximum use voltage (AC or DC). These ratings range from Class 00 (maximum use voltage of 500 volts AC) to Class 4 (maximum use voltage of 36,000 volts AC). Each class of gloves is designed for specific electrical applications and voltage levels, allowing workers to choose the appropriate level of protection for their tasks.

Physical Properties: The standard specifies various physical properties that the gloves must possess, including dimensions, thickness, elongation, and tensile strength. These properties ensure that the gloves have the strength and flexibility to withstand electrical work demands while maintaining dexterity and comfort for the wearer.

Electrical Properties: ASTM D120 requires gloves to undergo electrical tests to determine their resistance and dielectric strength. These tests verify the gloves' ability to provide effective insulation against electric shocks and the prevention of current flow through the gloves, thus protecting workers from electrical hazards.

Aging and Shelf Life: The standard also addresses the aging characteristics of rubber gloves and establishes guidelines for determining their shelf life. Gloves should be regularly inspected and tested to ensure their continued performance and replaced as the manufacturer or industry standards recommend. ASTM D120 currently requires gloves to be retested or replaced every six months.

Importance in Electrical Safety: ASTM D120 rubber gloves are critical in ensuring electrical safety for workers. Electrical shocks and arc flash incidents can have severe consequences, including serious injuries or fatalities. By using gloves that comply with ASTM D120, workers are equipped with a reliable barrier against electrical currents, reducing the risk of electrical contact and injury.

These gloves offer a layer of insulation that protects workers from electric shocks and burns during electrical installations, repairs, and maintenance. They are particularly vital for electricians, linemen, utility workers, and other professionals working in electrical utility, construction, and industrial settings.

Furthermore, adherence to ASTM D120 standards is essential for regulatory compliance. Occupational Safety and Health Administration (OSHA) and other regulatory bodies often require compliance with recognized industry standards to ensure the safety of workers.

ASTM D120 rubber gloves are indispensable in ensuring electrical safety by providing reliable insulation and protection against electric shocks and arc flash incidents. These gloves, manufactured and tested according to the stringent requirements of the ASTM D120 standard, offer workers the necessary protection when working with or near electrical systems. By selecting gloves that comply with this standard, employers can ensure the safety and well-being of their workforce and minimize the risk of electrical accidents.

You can view the entire catalog of ASTM D120 Compliant Rubber Gloves and Glove Kits

Author: Asa Dyer

Asa Dyer is the CMO of OEL Worldwide Industries