The Wolf at the Door [Arc Flash Hazards and Electric Vehicle Batteries]

Electric vehicles (EVs) are powered by high-voltage battery systems that can present a significant arc flash hazard. An arc flash is an electrical explosion that occurs when current flows through the air between two conductive objects, creating a high-temperature plasma that can cause severe burns, blindness, or even death.

When working on EV batteries, several potential sources of arc flash hazards need to be considered, including high-voltage electrical components, electrical connectors, and battery terminals. If the battery is damaged, mishandled, or short-circuited, an arc flash can occur, resulting in a dangerous electrical explosion.

The risk of an arc flash event is heightened when EV batteries are being repaired, replaced, or maintained. These activities can increase the likelihood of accidental contact or damage to the battery system. Additionally, the presence of flammable or combustible materials in the surrounding area can exacerbate the risk of an arc flash incident.

To mitigate the risk of an arc flash, following proper safety procedures and wearing appropriate personal protective equipment (PPE) is essential. Some of the most important precautions to take include:

Proper training: Only trained and qualified personnel should work on EV batteries. Workers must receive thorough training on recognizing, avoiding, and responding to arc flash hazards.

PPE: Workers should wear arc-rated clothing, insulated gloves, and face shields or goggles rated for arc flash protection. PPE should be properly fitted and maintained to ensure maximum protection.

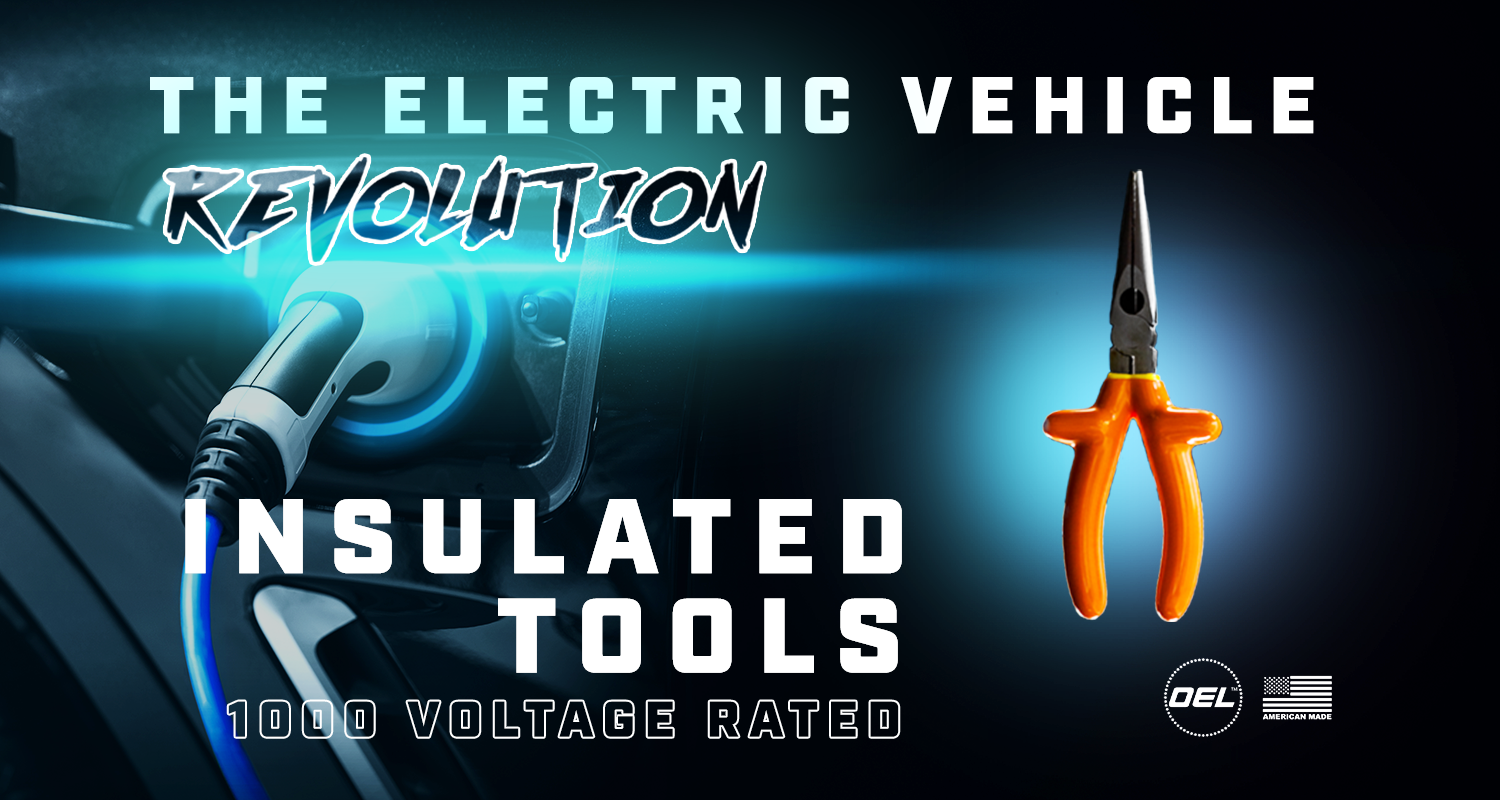

Non-conductive tools: Tools for working on EV batteries should be non-conductive, reducing the risk of accidental contact or short circuits.

Controlled environment: Work should be conducted clean, dry, and well-ventilated. The work environment should be free from flammable or combustible materials, reducing the risk of an explosion.

Proper handling: EV batteries should be handled carefully, not dropped, crushed, or punctured. Additionally, workers should never use metallic objects near the battery terminals or connectors.

In conclusion, the arc flash hazard of EV batteries is a safety concern that must be taken seriously. Proper safety procedures, including appropriate PPE, non-conductive tools, and training, can reduce the risk of an arc flash incident. By taking these precautions, workers can safely and effectively maintain and repair EV battery systems, ensuring the continued growth of sustainable transportation.

Author: Asa Dyer

Asa Dyer is the CMO of OEL Worldwide Industries